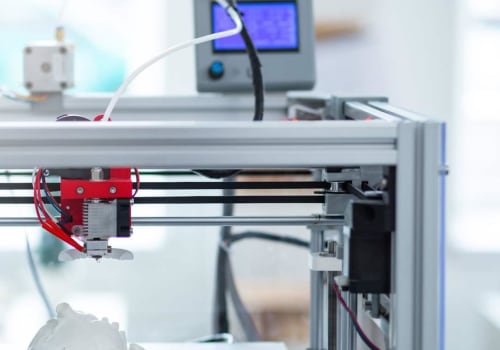

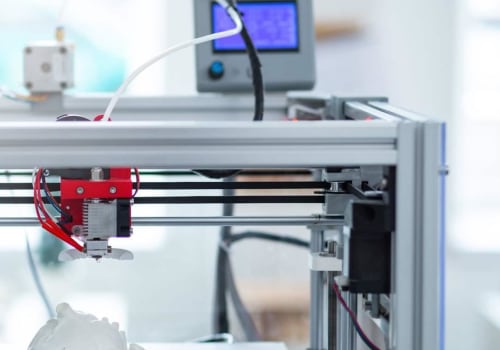

This approach uses 3D modeling software to build an object layer by layer; in the case of solid drugs, the 3D printer stacks ink with an excipient (inactive substances) in the drugs that are added for specific functions, such as improving stability and bioavailability, and the active pharmaceutical ingredient to print a finished product. However, 3D printing has the potential to revolutionize the pharmaceutical industry, and several companies are making headway in this field. As the pharmaceutical industry moves from mass production to a more personalized model, 3D printing of drugs has the potential to revolutionize the market. The MED 3D printing platform allows the customizable design of tablets, with different shapes and geometries that control the starting time, duration and interactions of drugs with the body.

Triastek is a world leader in pharmaceutical 3D printing, with 41 patents representing more than 20% of pharmaceutical 3D printing applications worldwide. Additive manufacturing, or 3D printing, is a tool that can enable the production of medicines on a small scale. Pharmaceutical companies must adopt new technologies, such as 3D printing, to carry out more personalized treatments, improve the efficiency of R&D, reduce costs and minimize waste. Its technology allows drugs to dissolve in seconds, a great advantage for people suffering from epilepsy or for patients who have problems swallowing.

A great deal of interest is being paid to 3D printing technology because of its immense potential for application in the pharmaceutical industry and other health sectors. Martin Burke, from the Howard Hughes Medical Institute, and his team of researchers developed a 3D printer to manufacture drugs using blocks of molecules. GSK is studying how to convert active pharmaceutical ingredients into curable ink to allow 3D printing of drugs. This review provides a detailed but very focused analysis of 3D printing technology, the summary of drug delivery technology based on 3D printing and its application in the pharmaceutical product development process.

Using its patented MED 3D printing technology, Triastek develops its own in-house drugs and partners with others to provide drug development solutions. Another important finding that came to light in the early years of the development of 3D printed drugs was a study conducted by the National University of Singapore (NUS) that showed that several drugs could be printed in a single pill. This association aims to promote the industrial applications of 3D printing technology and digitalization. Today, millions of people rely on prescription drugs on a regular basis for a variety of conditions and diseases.