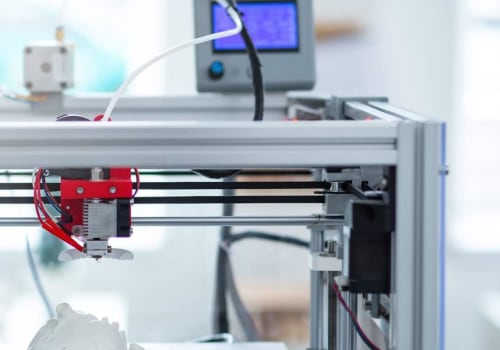

Because 3D printing offers a range of biocompatible and sterilizable materials, it helps medical device developers produce and test functional prototypes in a fraction of the time, which translates into more iterations, better products and less expensive care. With the growing demand for miniature medical devices, 3D printing has become the right choice for efficient manufacturing. The company, founded by a veteran and a paramedic, intends to produce millions of parts a year using 3D printing at its U.S.-based manufacturing facilities. UU.

Every day, the 3D printing service in India provides patients with low-cost personalized prostheses, implants and devices; allows surgeons to work more efficiently with customized instruments and models; and helps the medical device industries produce new and faster products. The cases are printed on SLA 3D printers in Tough 1500 resin, an elastic material that simulates the strength and rigidity of polypropylene. There is a growing demand for personalized, biocompatible and sterilizable components in the medical sector. The flexibility to produce highly customized products has allowed the wide use of 3D printing in the production of medical devices.

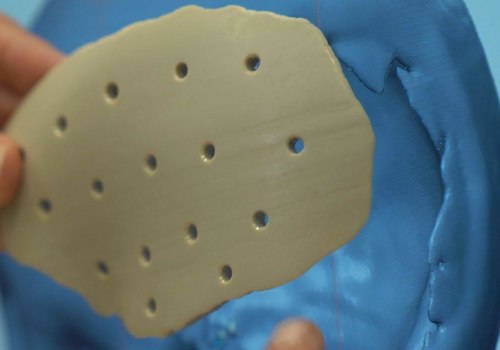

Let's look at the most common applications and real-world examples that highlight the versatility of 3D printing. SLA 3D printing offers a wide selection of 3D printing materials, including biocompatible materials, for a variety of medical and dental applications. Since SLS printing does not require specific support structures, it is ideal for complex geometries, such as interior elements, crevices, thin walls and negative elements. SLS 3D printing is ideal for robust and functional prototypes and end-use parts, such as prostheses and orthopedic appliances.

As 3D printing technologies continue to grow, healthcare professionals and academics will continue to seek new uses, from implants and surgical instruments to living tissues and organs, with 3D printing services in Chennai. The SLA technique is suitable for prototypes with tight tolerances and smooth surfaces, such as dental and medical parts, while the SLS is the best option for complex geometries, such as prostheses. Finally, this article identifies and analyzes the important applications of 3D printing for health research and development. Start now or expand your in-house production with Formlabs, a cutting-edge and proven partner in medical 3D printing.