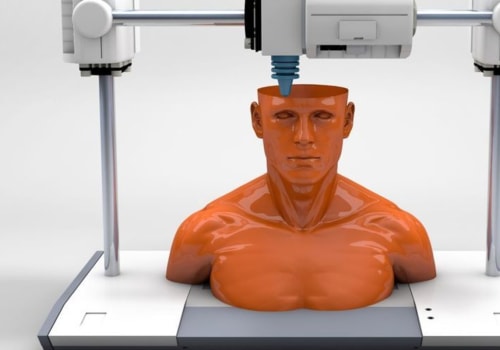

An example of how 3D printing can reduce costs is that the technology tends to use less energy than traditional manufacturing processes. Leveraging 3D printing technology could dramatically reduce that number and improve operational efficiency in an operating room. There are hundreds of 3D printing applications in the medical field, and more applications will emerge as the technology continues to develop and improve. A 3D printer was used to produce a mold for human ears and noses that are needed in several medical procedures.

Every year, 3D printing offers more and more applications in the field of health that help save and improve lives in ways never imagined before. More than 90 percent of the top 50 medical device companies use 3D printing to create accurate prototypes of medical devices, templates and accessories to simplify testing, in addition to directly 3D printing medical devices. For example, 3D printing can improve existing surgical procedures and can aid organ transplantation. Currently, doctors use models produced by 3D printing based on scanned patient data to improve the diagnosis of diseases, clarify treatment decisions, plan and, in some cases, even practice the chosen surgical interventions before the actual treatments.

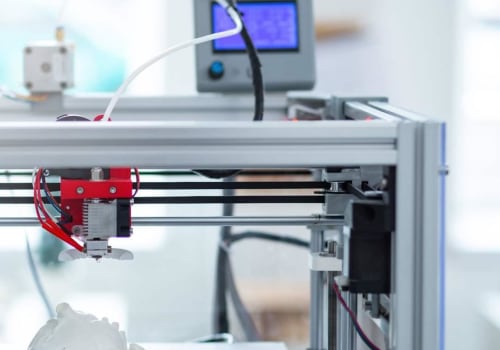

With 3D printing in the healthcare industry, doctors can create tools that precisely follow a patient's unique anatomy. The SLA is an excellent choice for highly detailed anatomical models, prototypes of medical devices that require tight tolerances and smooth surfaces, as well as molds, tools, patterns and functional end-use parts. With Draft Resin, Formlabs' SLA printers are also the fastest options for printing large prototypes in 3D, up to 10 times faster than FDM. DMLS and SLM 3D printers can create tough, precise and complex metal products, making this process ideal for a variety of medical applications.

Manufacturers can also use the first 3D printed parts to support clinical trials or early commercialization while the final design is still being optimized. Elsewhere, MIT researchers have also identified 3D printing as an optimal means of producing more comfortable prosthetic cavities. The biggest advantage of these processes is obviously the materials, since DMLS and SLM 3D printers are capable of producing high-performance end-use medical devices and components from metal. It's no surprise that 3D printing is more than just an industry trend: technology has the power to truly transform the industry for the better.